In recent years, with the increasing demand for textiles with both functionality and beauty, a new type of fabric called "polyester four-sided stretch" has quietly risen. Its emergence is not only a technological innovation, but also an innovation storm of traditional clothing design concept.

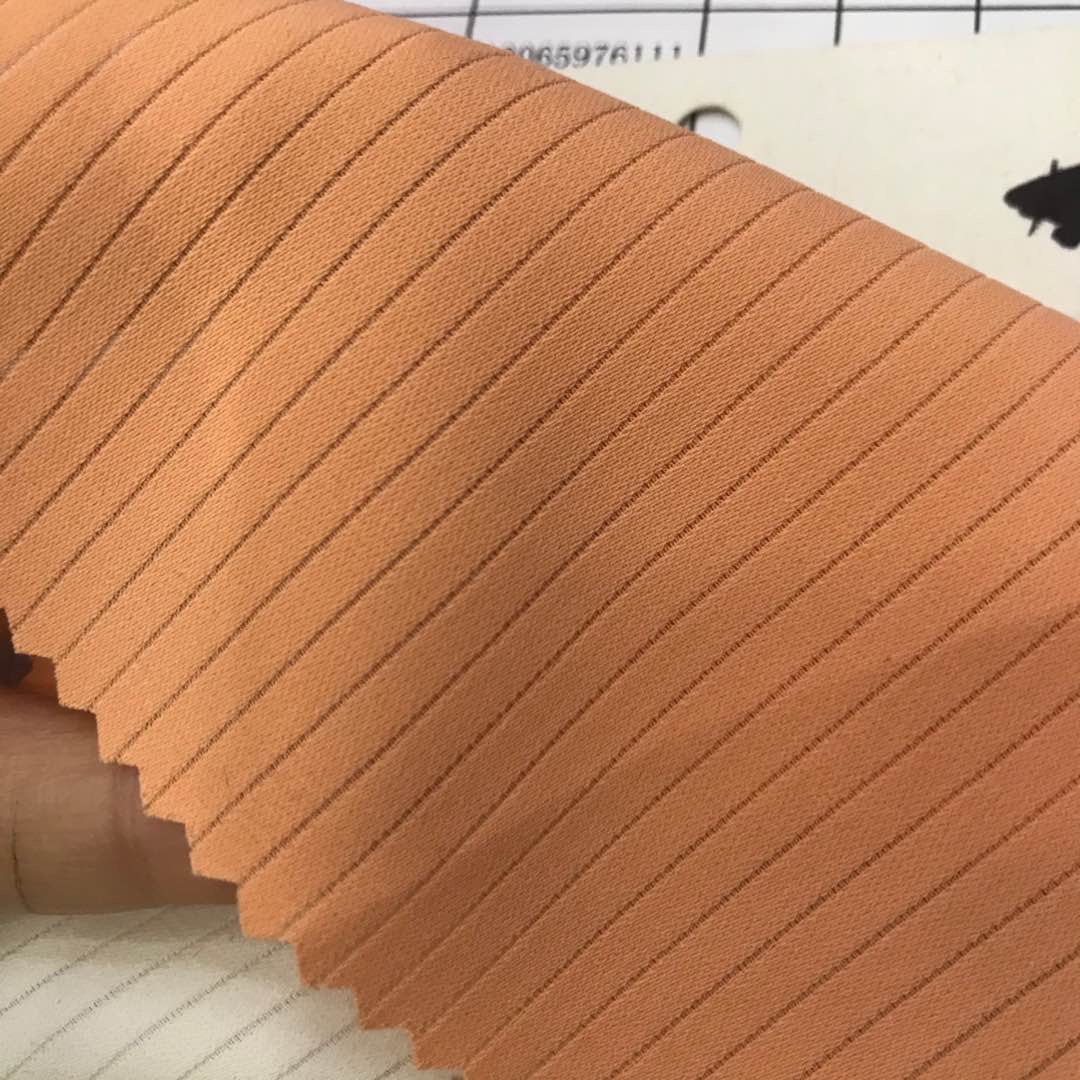

This high-tech fiber stands out for its unique physical and chemical properties. First of all, it has a very high elastic recovery ability, even after repeated stretching can maintain the original shape; secondly, its quick-drying and breathable function allows the wearer to still feel refreshing in the hot summer. Experimental data show that under the same conditions, compared with ordinary cotton fabrics, polyester four-sided stretch fabric drying speed increased by nearly three times as much.

For the long-standing and much-loved traditional dress-the Hanfu horse dress, this fabric undoubtedly brings a new vitality. With the help of strong ductility to support more complex three-dimensional tailoring design, making the overall line more smooth and beautiful, while greatly improving the wearer's freedom of movement. Imagine dancing at an antique wedding without worrying about the sense of restraint interfering with elegant posture, all because of the possibilities given by this technological advancement.

At the same time, the workplace elite is constantly looking for an ideal dress plan that meets professional norms and takes into account personal comfort. The fashionable shirt made of polyester stretch on all sides fits this demand. They not only retain the crisp appearance required for formal occasions, but also increase the space margin for flexible rotation of the shoulder and back. Even taking fitness classes after a busy day is no longer a luxury.

In addition, the products also show amazing cross-scene adaptability. There is no sense of disobedience between the solemn corporate annual meeting scene and the relaxed and comfortable family gathering atmosphere. No matter what kind of environment, it can always be presented to the surrounding people in the best state to leave a deep impression.

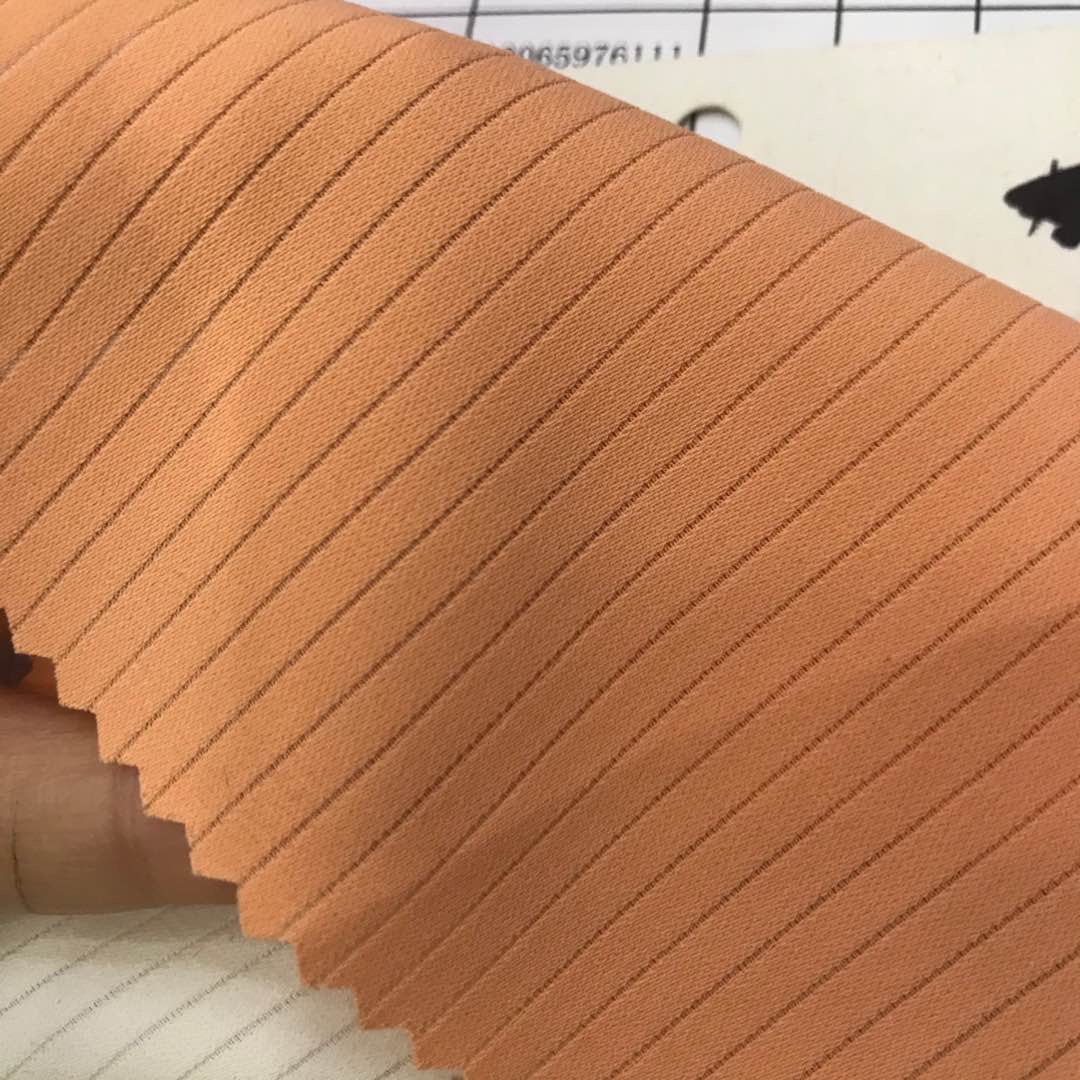

Behind every high-quality fabric is the result of the unremitting efforts of the production team. Strict quality control measures are implemented throughout the process from the selection of raw materials to the delivery of finished products to ensure that there are no defects left in the past. For example, a special laboratory is set up for the dyeing and finishing process to simulate extreme conditions to test whether the stability index value meets the standard, etc.

Looking ahead, we can expect more exciting changes to take place in the field. Artificial intelligence-aided design tools will accelerate the process of shortening the research and development cycle of new materials, and the popularization of green production processes under the guidance of the concept of sustainable development will also contribute to reducing the burden on Mother Earth. Let's look forward to this day as soon as possible!