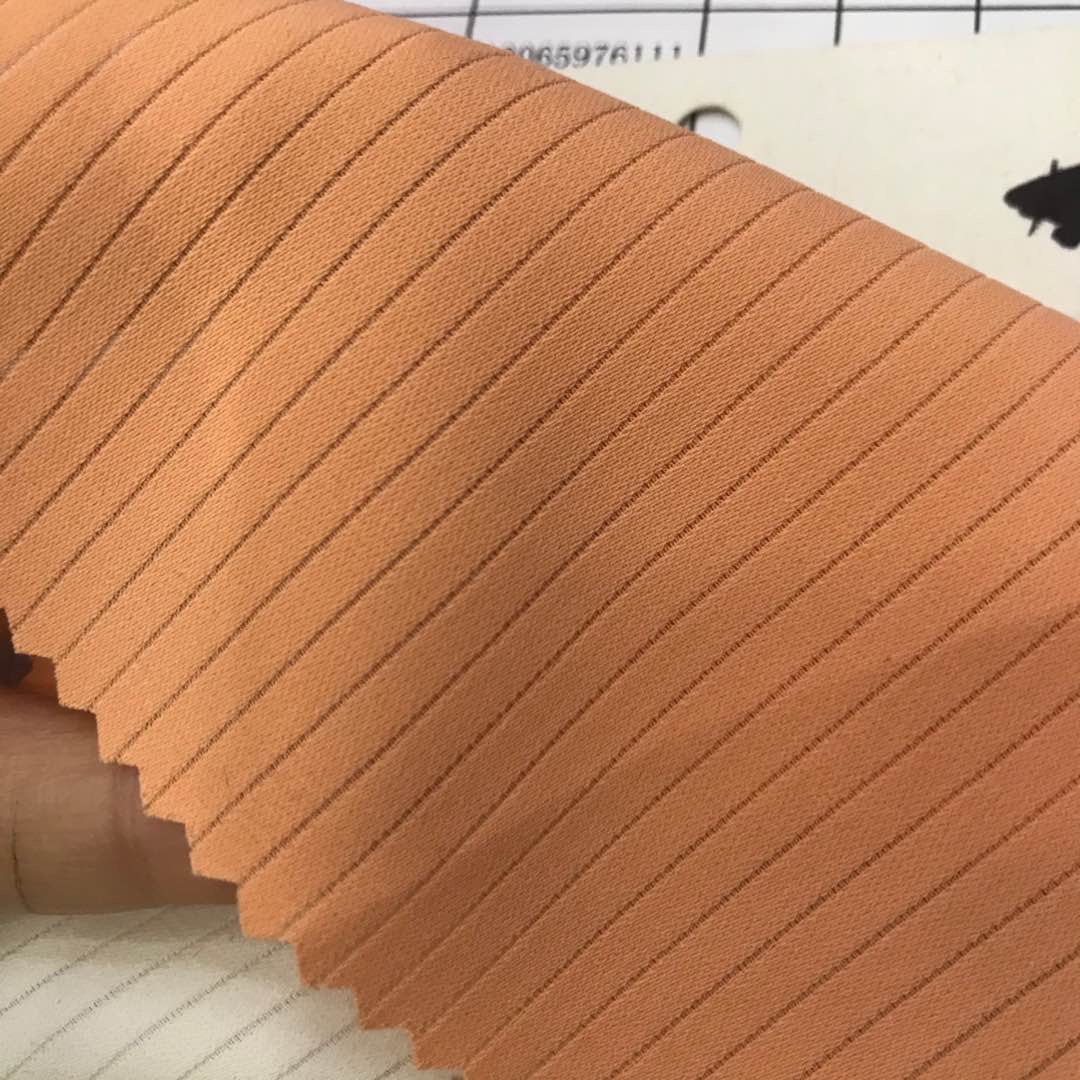

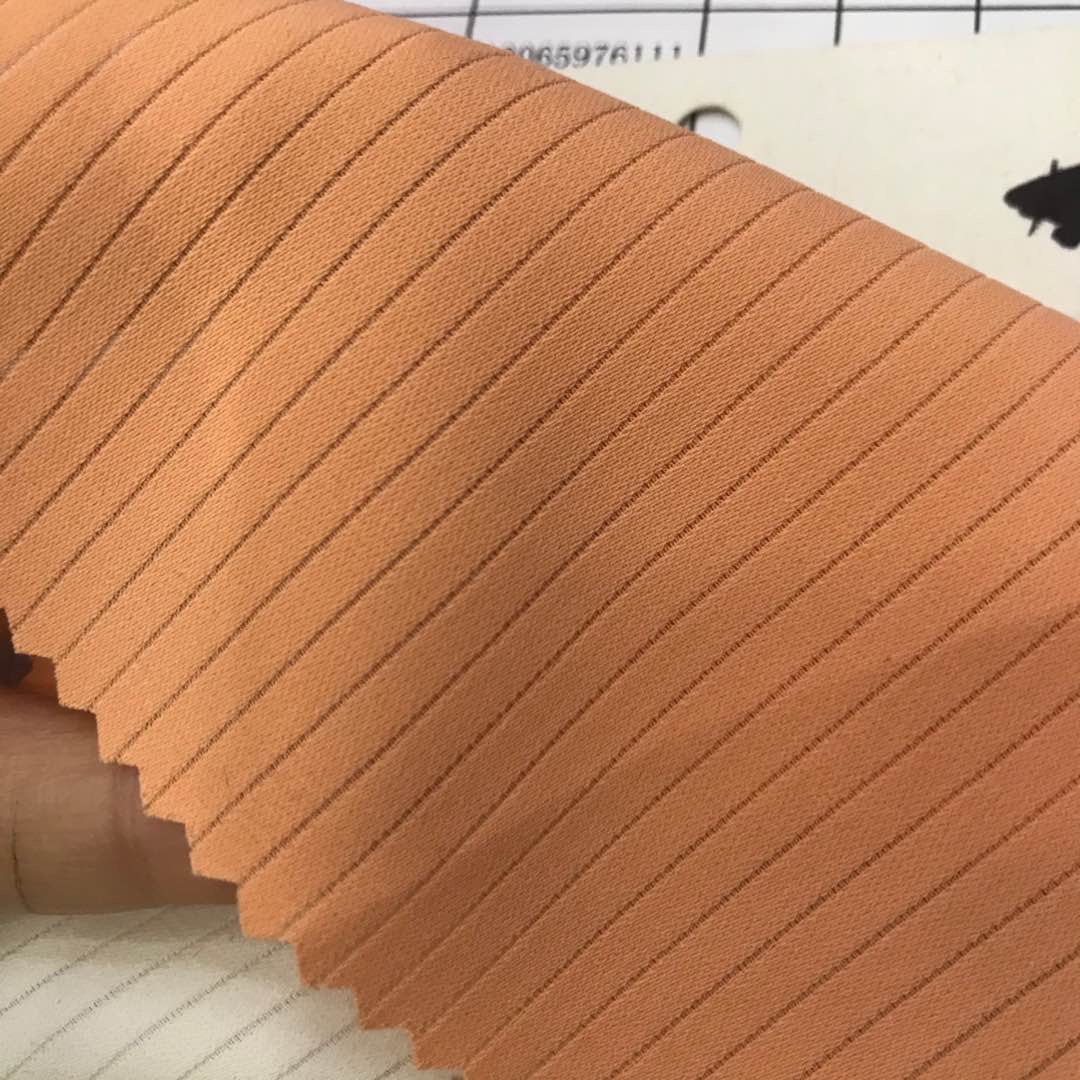

Polyester Four-Sided Stretch Woven Fabric for Hanfu Horse Skirt & Fashion Shirts

In an era where heritage meets innovation, a quiet revolution is unfolding in the world of textiles—one thread at a time. The resurgence of Hanfu has ignited a cultural renaissance, but today’s wearers demand more than beauty; they seek comfort, durability, and adaptability. Enter a breakthrough fabric: polyester four-sided elastic woven material, thoughtfully engineered to honor tradition while embracing modern life.

When Eastern Aesthetics Meet Future-Forward Weaving Technology

From ancient silk looms to today’s high-performance synthetics, textile evolution mirrors cultural transformation. Traditional Hanfu once relied on delicate natural fibers that demanded careful handling—beautiful, yet fragile. As modern lifestyles call for resilience without sacrificing grace, designers are turning to advanced polyester weaves that preserve aesthetic integrity while enhancing functionality.

Nowhere is this more evident than in the revival of the horse-face skirt (mamianqun), a hallmark of Ming dynasty fashion known for its structured panels and graceful movement. Its complex geometry poses a challenge: how to maintain shape during motion without restricting the wearer? The answer lies in four-way stretch technology—a seamless fusion of structure and suppleness that allows the skirt to move *with* the body, not against it.

The Kinetic Philosophy Woven Into Every Inch

What sets four-sided stretch apart isn’t just elasticity—it’s intelligent mobility. Unlike conventional woven fabrics that stretch primarily along the weft, this advanced textile expands equally across both warp and weft threads, enabling dynamic freedom in all directions. This means raising your arms beneath wide sleeves or sitting cross-legged doesn’t distort the silhouette; instead, the fabric rebounds gracefully, maintaining its intended form.

Imagine the contrast: rigid cottons that crease under strain versus this adaptive weave, which responds like a second skin. It bridges two worlds—the voluminous elegance of classical Hanfu and the sleek precision of contemporary tailoring—making it equally suited for ceremonial wear and urban reinterpretations.

More Than Hanfu: Conquering the Fashion Shirt Realm

While rooted in historical inspiration, this fabric refuses to be typecast. Designers are now deploying it in minimalist shirts that redefine professional elegance. Picture a crisp button-down with soft drape, moving fluidly through subway commutes and boardroom meetings alike. Thanks to inherent wrinkle resistance and shape retention, these shirts emerge from bags and briefcases looking freshly pressed.

A leading Shanghai-based designer notes: “We used the same bolt to create a draped Hanfu ensemble and a sculptural shirt. One fabric, two languages—one poetic, one pragmatic.” That versatility speaks to a new generation of consumers who value multifunctional pieces that transition seamlessly between contexts.

The Language of Touch: What Your Skin Knows Before Your Eyes Do

Fabric is ultimately experienced through sensation. Run your fingers over this polyester blend and you’ll notice a silky smoothness with a whisper of luster—not flashy, but dignified. At approximately 120g/m², it strikes a balance between substance and breathability, offering coverage without overheating.

Rigorous testing confirms its endurance: after 50 wash cycles, dimensional stability remains above 96%, with minimal pilling or fading. In humid summers, moisture-wicking properties reduce stickiness; in dry winters, static buildup is nearly undetectable. Whether worn next to skin or layered under jackets, it adapts effortlessly to environmental shifts.

The Designer’s Secret Weapon in the Studio

For creators, this fabric unlocks unprecedented creative latitude. Its forgiving nature reduces cutting waste by up to 18% compared to stiff silks, especially when shaping curved seams or intricate pleats. Digital prints achieve exceptional color fidelity, with ink absorption consistent across batches—critical for limited-edition runs.

Better still, it supports rapid prototyping. Because it behaves predictably during sewing and pressing, sample turnaround times shrink dramatically. Small studios can iterate faster, respond to trends quicker, and scale sustainably—all without compromising quality.

From Cultural Symbol to Wearable Innovation

Why are younger consumers embracing reimagined traditions? Not out of nostalgia, but identity. They want garments that reflect their roots yet fit their lives. This fabric enables exactly that: a horse-face skirt worn with sneakers, or paired with a tailored blazer for hybrid events. It’s no longer about authenticity defined by rigidity, but relevance achieved through reinvention.

And within sustainable fashion dialogues, recycled polyester variants of this fabric are emerging—offering reduced carbon footprints without sacrificing performance. Tradition evolves not by resisting change, but by weaving it in.

Sewing Tips from Seasoned Craftspersons

Working with elastic wovens requires nuance. Use microtex or ballpoint needles to prevent snags, and opt for polyester thread that matches the fabric’s recovery rate. Adjust presser foot pressure slightly lower to avoid compressing the weave—this maintains edge smoothness, especially on bias cuts. For seam finishes, consider a narrow rolled hem or twin needle setup; these prevent rolling while preserving stretch integrity.

With attention to tension balance and finishing technique, even complex patterns unfold cleanly—proving that innovation serves both artistry and execution.

This isn’t just fabric. It’s a dialogue between past and future—one that moves, breathes, and inspires.